News

Two Consecutive Northwest Tech Students Chosen as Succeeding SkillsUSA Kansas State President

Goodland, KS. (11/09/2020) – For the second year in a row, Northwest Tech has announced that a current student has been chosen as the SkillsUSA Kansas State President.

Logan Klein was recently announced as the succeeding SkillsUSA Kansas President, accepting the position from a former peer, Juan Colegio.

Formerly, Juan Colegio was named as the SkillsUSA Kansas President for the 2019/2020 school year. Colegio is a graduate of Northwest Tech’s CSI program and is currently finishing his Criminal Justice degree at Fort Hays State University. While attending Northwest Tech, Colegio served as the Student Body President and was very active in several groups and organizations.

Current SkillsUSA Kansas President, Logan Klein, is finishing his final year of the Carpentry program and plans to return to Yuma, Colorado to open a small handyman business. Klein chose carpentry because he enjoys designing and fabricating solutions to a wide variety of problems in residential construction.

The newly elected officers were announced at a virtual recognition ceremony. Before being selected, candidates went through an application process including written exams, essays, interviews and a speech.

“Becoming a State SkillsUSA President takes dedication and persistence”, said Northwest Tech’s SkillsUSA administrator, Rory Kling, “Having repeat State Officers from Northwest Tech will help advocate for the skilled trades and vocational education throughout the state of Kansas.”

SkillsUSA is a Career and Technical Education partnership of students, teachers, and industry working together to ensure America has a skilled workforce. SkillsUSA provides educational experiences for students in leadership, teamwork, citizenship, and character development by building and reinforcing self-confidence, work attitudes, and communications skills.

Northwest Tech Implements mikeroweWORKS Foundation’s Work Ethic Certification

Northwest Tech one of the first to implement the mikeroweWORKS Foundation’s Work Ethic Certification

GOODLAND, Kan. – NOV. 4, 2020 – Northwest Tech has announced that it is one of the first post-secondary schools to participate in the national expansion of the mikeroweWORKS Foundation’s pilot curriculum, known as the MRW Work Ethic Certification. This program is currently underway at Northwest Tech and accredited by the National Coalition of Certification Centers (NC3). The expansion includes an additional 20 post-secondary NC3 leadership schools across the United States.

The mikeroweWORKS Foundation collaborated with WSU Tech to create and develop the MRW Work Ethic Certification with support from Koch Industries and the Charles Koch Foundation. This program is an extension of the mikeroweWORKS Foundation’s S.W.E.A.T. Pledge and examines the importance of work ethic, personal responsibility, delayed gratification, and a positive attitude. Students who successfully complete the program will receive an industry-recognized NC3 certificate. For more information about the MRW Work Ethic Certification, click here for the media kit.

“No matter how quickly the world changes, the qualities of successful individuals are still the same,” said Mike Rowe, founder and CEO of the mikeroweWORKS Foundation. “The principles of hard work, determination, and respect for others are always in demand and a big part of our Work Ethic Scholarship Program. Many employers have reached out to my foundation and asked if those principles could form the basis of a new kind of curriculum—a guide, of sorts, to help bolster the importance of these qualities in the American workforce.”

The certification program is currently administered through NC3’s online platform, which 20 NC3 Leadership Schools will implement in the fall 2020 and spring 2021 semesters. Nearly 1,800 students have completed the work ethic curriculum to date.

"We value the importance of developing a strong work ethic in our students before they graduate and head into the workforce," said Northwest Tech President Ben Schears. "Adding the MRW Work Ethic Certification that is NC3-certified will strengthen our student experience and add an additional certification relevant to employer needs."

To learn more about how to bring the MRW Work Ethic Certification to your school, visit mikeroweworks.org/sweat.

###

About Northwest Kansas Technical College

The mission of Northwest Kansas Technical College, as an institution of higher learning, is to prepare individuals for gainful employment in technical and professional careers, productive personal lives, and lifelong learning.

Northwest Tech is fully accredited by The Higher Learning Commission and is a Kansas Board of Regents institution. For more information, visit NWKTC.EDU.

About mikeroweWORKS Foundation

The mikeroweWORKS Foundation is a 501(c)(3) public charity that works hard to debunk myths and misperceptions about the trades and help close the skills gap. As the CEO of mikeroweWORKS, Mike speaks regularly about the country’s dysfunctional relationship with work and challenges the persistent belief that a four-year degree is automatically the best path for the most people. The Foundation provides financial assistance to people getting trained for skilled jobs through its annual Work Ethic Scholarship Program. Since its inception, mikeroweWORKS has helped grant, or facilitated the granting of, more than $5 million in support of technical and vocational education. To learn more, visit mikeroweworks.org.

About NC3

NC3 was established to help build a workforce prepared to meet the needs of today’s and tomorrow’s industries by connecting employers and educational institutions in synergistic partnerships that foster effective training, elevation of skilled careers, and employment opportunities. In fulfilling its mission, NC3 builds deep industry-educational partnerships and develops, implements and sustains industry-recognized portable certifications built on national skills standards. We envision an industrial labor market where all workers have jobs they need to thrive and all companies have well-trained employees they need to operate and grow. Learn more at www.nc3.net.

Northwest Tech Receives $500,000 Grant

Northwest Tech Receives $500,000 Grant- Goodland, KS. (11/03/2020)

Northwest Tech is proud to announce the recent award of a $499,995 grant to be directed toward advanced equipment and training to be integrated into the college’s Engineering Technology program. The grant comes to the college through an initiative launched by the Kansas Department of Commerce in response to the COVID-19 pandemic to expand opportunities for education in advanced manufacturing and automation throughout the state.

Northwest Tech will utilize the grant funds to secure several new cutting-edge pieces of manufacturing equipment for the Engineering Technology program and expand curriculum to include new coursework and training in advanced manufacturing and automation. In the near-term it will allow students to choose between two pathways during their second year in the program; civil engineering or mechanical engineering. In addition to program changes, the college will be able to partner with area high schools and community members to deliver courses online and on-site in G-Code; the programming language used for CNC programming.

The goal is for the equipment enhancements to meet the shifting needs of industry partners and the state’s workforce involved in advanced manufacturing and to engage the college in regional economic development. It is the college’s hope to see area community members and businesses bring new concepts for product creation to the lab to allow students to draft, digitize in CAD, and prototype new products for the marketplace. This grant will improve Northwest Tech’s connection with Kansas’ manufacturing industry by providing access to innovative technology to students and broaden the labor pool to attract industry to the area. It is the college’s hope to see area community members and businesses bring new concepts for product creation to the lab to allow students to draft, create and prototype for new products.

“One of the unique responsibilities we have as institutes of higher education, is to position the college in a manner that not only responds to the needs of our regional economy, but also helps to drive and develop new opportunities”, said President Ben Schears, “The submission our team at Northwest Tech has developed for this grant accomplished exactly that; it is both responsive and focused on growth.”

Within the existing framework of our Engineering Technology program, the students are trained to become design technicians in either the civil engineering field or mechanical engineering/manufacturing fields. This project allows the program to greatly advance the skill set of the students to not only design the parts, but to see their concepts come to fruition through the use of high-tech automation and industry integrated technology. This will strengthen their entry opportunities in Kansas advanced manufacturing fields and drive innovation in regional industry throughout our 17-county Northwest Kansas service area.

"Being awarded this grant from the Department of Commerce is a game changer in many ways.” said Engineering Instructor Michael Zimmerman, “Not only will our students have access to new technology in the areas of carbon fiber & metal 3D printing, robotic welding, and multi-axis CNC machining, but the entire service area will have access to this technology as some courses will be available online and we will rely on community based projects to help deliver our curriculum to the students. This means that rural manufactures, community members, and regional high school students can gain access to the program as students or as project partners. “

For more information about the Engineering & Drafting Technology program, please visit NWKTC.EDU

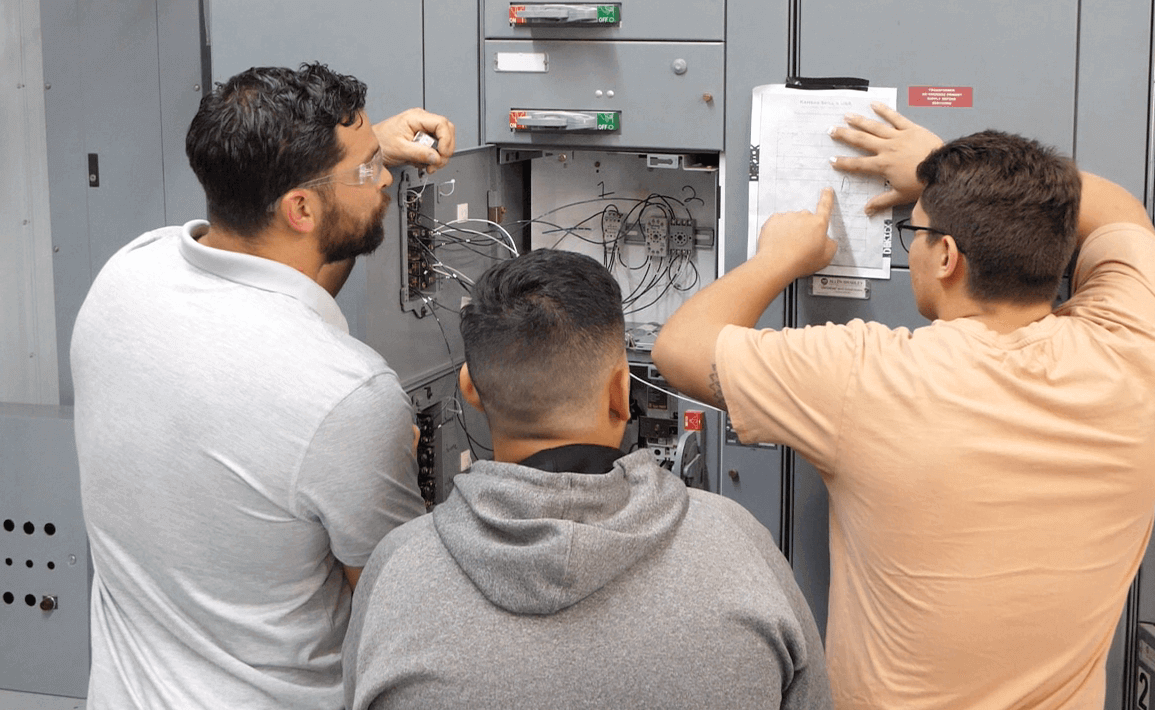

Engineering Instructor, Mike Zimmerman, working in the current Advanced Manufacturing Lab. The Advanced Manufacturing Lab will soon expand into an 1800 sq ft space to accommodate the new equipment.

Northwest Tech Announces New Collision Repair/Auto Body Instructor

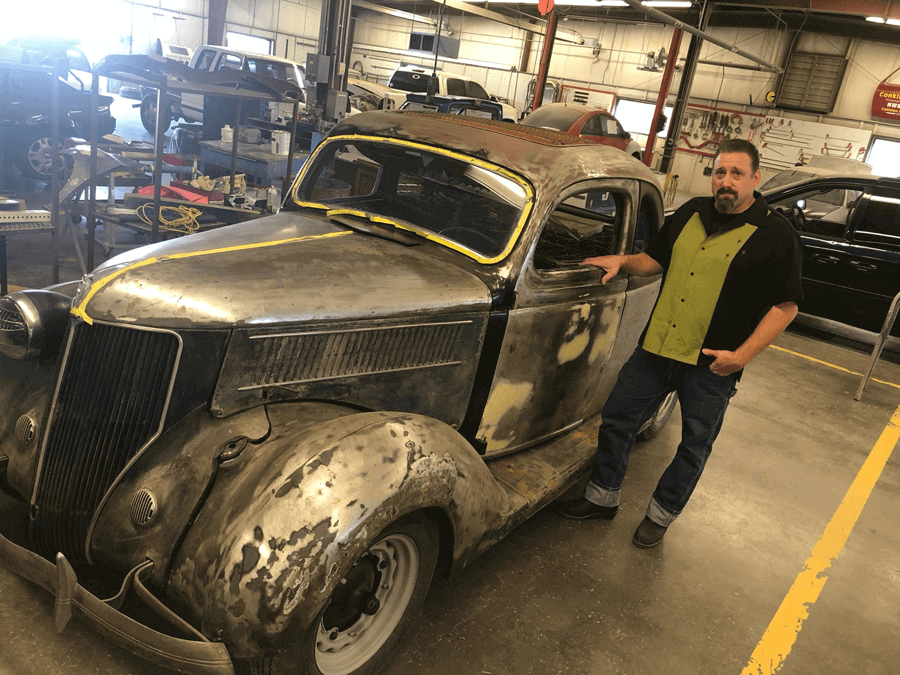

Northwest Tech has announced Matt Murray as the new Collision Repair/Auto Body Technology instructor. As a graduate of the program, the Goodland native brings more than 25 years of auto body experience to the classroom. Murray owns “Murray’s Kustoms” which has been in business for over 16 years. Murray is also involved with the local Auto Club, “Bricktop Cruisers”, as President for over a decade.

While holding several industry-related certifications, Murray has a skillset that surpasses the typical body and refinish technician. Murray’s special interests include custom body and paint work, choptops, metal fabrication, airbrushing, pinstriping, upholstery, suspension, glass, trim, and soda blasting.

“I want to bring my real-world industry experience to this program and make sure my students are entering the workforce with a valuable, steadfast craftsmanship”, said Murray, “My main passion is custom paint and restoration. I’m hoping to bring out the inner artist in my students as we work on jobs that require them to customize and modify projects.”

Murray is *metal fabrication, form metal into something like patch panel, custom painting, hand pinstripping, enhancing curriculum w also adding to the advisory ewith industry patners that specialixe int thes learn trendy stuff, not just a parts changer- teach them more patience and fitting their skill to each individual project. Art, craftsmanship and ksill- not just a parts changer, implement into second year – retention,

Northwest Tech’s Auto Body program primarily focuses on painting, safety, preparation, application and troubleshooting. Students in Auto Body also learn the basics of safety, metal fabrication, auto detailing, mechanical and electrical repair, estimating and other topics, along with painting.

If you are interested in learning more about Northwest Tech’s Auto Body program, please visit NWKTC.EDU or call (785) 890-3641.

Pictured Above: Auto Body Instructor, Matt Murray

Pictured Above: Instructor Matt Murray, stands in front of his airbrushed artwork he did back when he was a second year student at Northwest Tech.

Northwest Tech Announces New Carpentry Instructor

This fall, Northwest Tech welcomed a new Carpentry instructor, Joseph Dobbs. Dobbs is a Northwest Tech alumni, however, he majored in Computer Graphic Design back in 2005. Dobbs spent the last 12 years working in the construction industry alongside his father.

“Carpentry was something I was raised doing. It’s my father’s trade and so by proximity I inherited the skills, knowledge and passion required for the job”, said Dobbs, “To this day it still gives me immense joy to finish a project and have a satisfied customer. It’s always fulfilling to finish an apartment, office, shop, building or home and step back to realize you left a thumb print that will bring years of use for the customer and or family.”

Dobbs worked for his family’s construction company as soon as he was able to go to work, and the experience helped foster his desire to instruct. He finds sharing his knowledge of the industry very rewarding, and he is motivated to see students graduate from Northwest Tech and enter the workforce with pride and confidence.

Dobbs’ vision for the program is to put a bigger emphasis on instructional class time as well as the hands-on learning experience currently offered. This means incorporating a few more courses he believes are necessary, without losing the time devoted to the hands-on projects.

“I want my students to have a big advantage going into industry”, said Dobbs, “I want my students to leave Northwest Tech with their degree and a Contractor's License in hand. That’s my goal.”

The Carpentry program at Northwest Tech is a broad program where courses are focused on various disciplines with work-based experience. Students will learn from lectures, demonstrations, shop time, and campus work projects alongside course material. Students are prepared for employment in the residential-commercial carpentry construction industry by the end of the two-year program. The goal of the program is to prepare students eventually to gain employment in various levels in construction such as; journeyman carpenter, job site foreman, construction superintendent, or project manager. The curriculum corresponds directly alongside the industry's green building and energy efficient standards. The students’ ability to apply learned concepts to mastered skills is monitored through projects requiring industry-standard skill levels of increasing difficulty and through building maintenance, renovation, and new construction assignments on-campus and in the surrounding community.

To learn more about the Carpentry program, visit NWKTC.EDU or call (785) 890-3641.

Pictured Above: Instructor Joseph Dobbs

SEARCH

SEARCH